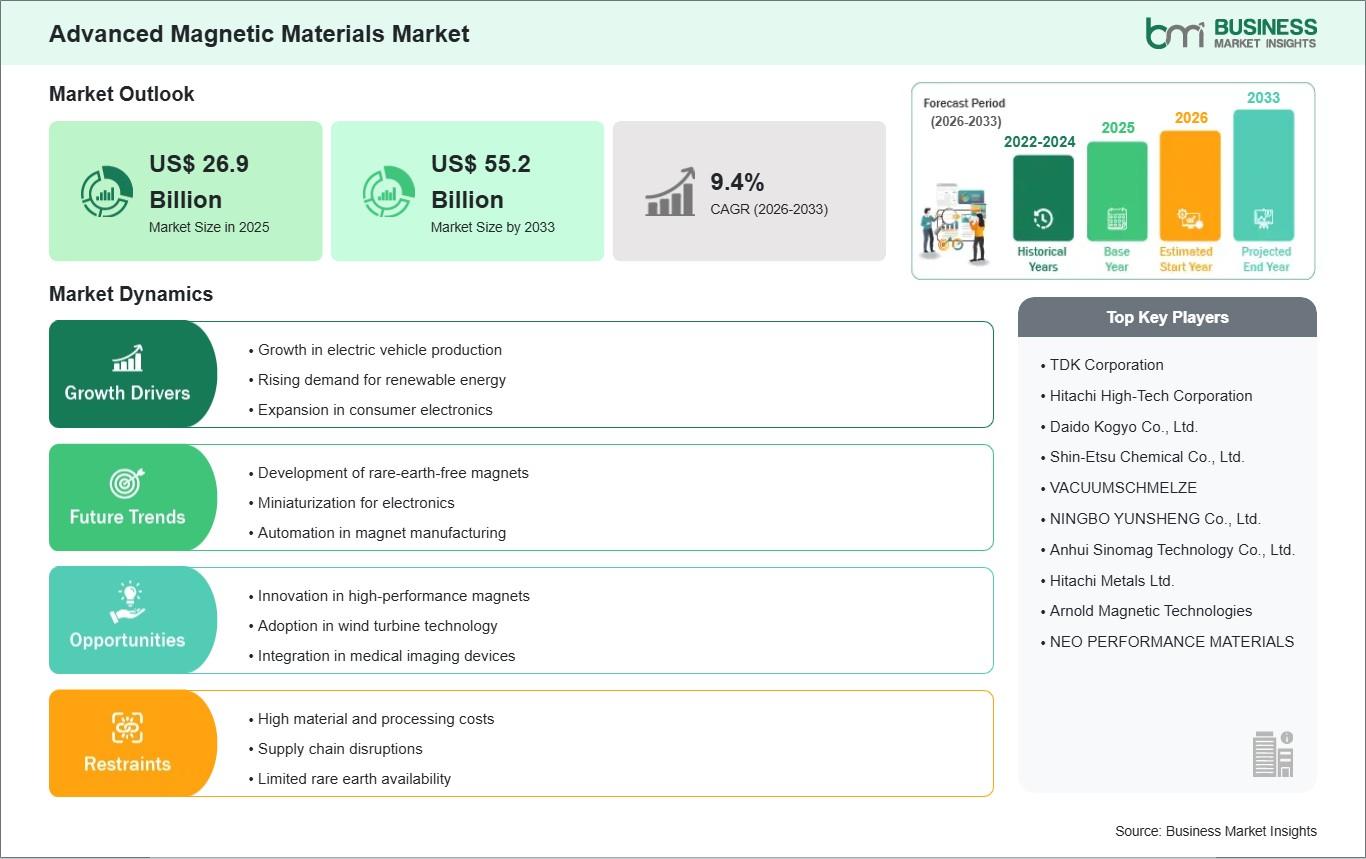

According to The Insights Partners Global Advanced Magnetic Materials Market is witnessing sustained double-digit demand growth, driven by electrification, renewable energy, and miniaturized electronics across global manufacturing hubs. Rising investments in high‑performance magnets for electric vehicles, industrial automation, and medical technologies are reshaping competitive dynamics and innovation priorities for leading players.

Market overview

Advanced magnetic materials are engineered soft, semi‑hard, and permanent magnets designed to deliver high energy density, thermal stability, and superior efficiency in demanding applications. These materials are now embedded in critical systems such as traction motors, industrial drives, MRI equipment, consumer electronics, and smart grid components, making them strategically important to multiple industries.

Download Sample PDF - https://www.businessmarketinsights.com/sample/BMIPUB00032429

The market is evolving from traditional bulk magnets to high‑performance rare‑earth and advanced soft magnetic alloys that support lighter, more compact, and more energy‑efficient designs. This shift aligns with global priorities around decarbonization, electrification of transportation, and digitalization of industrial infrastructure.

Key growth drivers

- Rising adoption of electric and hybrid vehicles is one of the strongest demand engines, as traction motors, inverters, onboard chargers, and ADAS sensors rely heavily on advanced magnetic components. Automakers are increasingly partnering with magnet producers to secure long‑term supply and optimize motor designs for range, performance, and cost.

- Expansion of renewable energy and smart grids is accelerating the use of advanced magnetic materials in wind turbine generators, power electronics, and energy storage interfaces. These materials help improve conversion efficiency, reduce system losses, and support more compact and reliable designs in harsh operating environments.

- Rapid industrialization and automation are boosting demand from motors, actuators, sensors, and robotics used in manufacturing plants, logistics, and infrastructure projects. Emerging economies are particularly important, as smart city programs and infrastructure upgrades increasingly specify high‑efficiency equipment that incorporates advanced magnetic solutions.

Additional growth momentum comes from miniaturized consumer electronics, advanced medical imaging, and implantable and therapeutic devices that require precise, stable magnetic performance.

Material types and applications

- Soft magnetic materials are widely used in transformers, inductors, and motor cores where low core loss and high permeability are critical for efficiency. Ongoing R&D focuses on new alloys and processing routes that reduce energy losses at higher frequencies, enabling more compact power electronics.

- Permanent magnetic materials, including rare‑earth and alternative compositions, power traction motors, industrial drives, speakers, and sensors in automotive and electronics. Manufacturers are working on formulations that balance magnetic performance, cost, and reduced dependence on constrained raw materials.

- Semi‑hard magnetic materials serve in data storage, magnetic recording, and certain actuator and sensor roles where controlled magnetization and demagnetization are required. As device architectures evolve, these materials support higher data densities and improved reliability in compact formats.

End‑use industries span automotive, electronics, industrial machinery, power generation, medical, and other niche sectors such as aerospace and defense.

Trending keywords –

Aerospace Materials Market - Outlook (2022-2033)

Carbon Capture Materials Market - Outlook (2022-2033)

Seed Coating Materials Market - Outlook (2022-2033)

Competitive landscape and strategic focus

The competitive landscape is moderately consolidated around globally established magnet and specialty materials manufacturers, alongside agile regional players. Key companies include Hitachi Metals, TDK Corporation, Daido Steel, Shin‑Etsu Chemical, Arnold Magnetic Technologies, Electron Energy Corporation, Neo, Ningbo Yunsheng, Vacuumschmelze, Yantai Dongxing Magnetic Materials, DMEGC, Bunting, Dexter Magnetic Technologies, and others.

Leading participants are prioritizing several strategic themes.

- Innovation in high‑performance magnets and soft magnetic alloys to deliver higher efficiency, temperature resilience, and miniaturization benefits across EV, industrial, and electronics platforms.

- Diversification and localization of raw material supply, including rare‑earth sourcing, processing, and recycling, to mitigate price volatility and geopolitical risks.

- Sustainability‑driven manufacturing, with emphasis on lowering environmental impact, improving recyclability, and developing eco‑friendly alternatives to conventional rare‑earth systems.

Challenges and future opportunities

- Dependence on critical raw materials, particularly rare‑earth elements, exposes the market to supply constraints, price swings, and environmental concerns around mining and processing. These factors are motivating investment in recycling, substitution, and more resource‑efficient magnet designs.

- High production and processing costs for advanced alloys can limit adoption in highly price‑sensitive applications, especially in emerging economies. Process optimization and scale‑up are therefore central to improving cost‑competitiveness without compromising performance.

About Us:

The Insight Partners is a one stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Device, Technology, Media and Telecommunications, Chemicals and Materials.