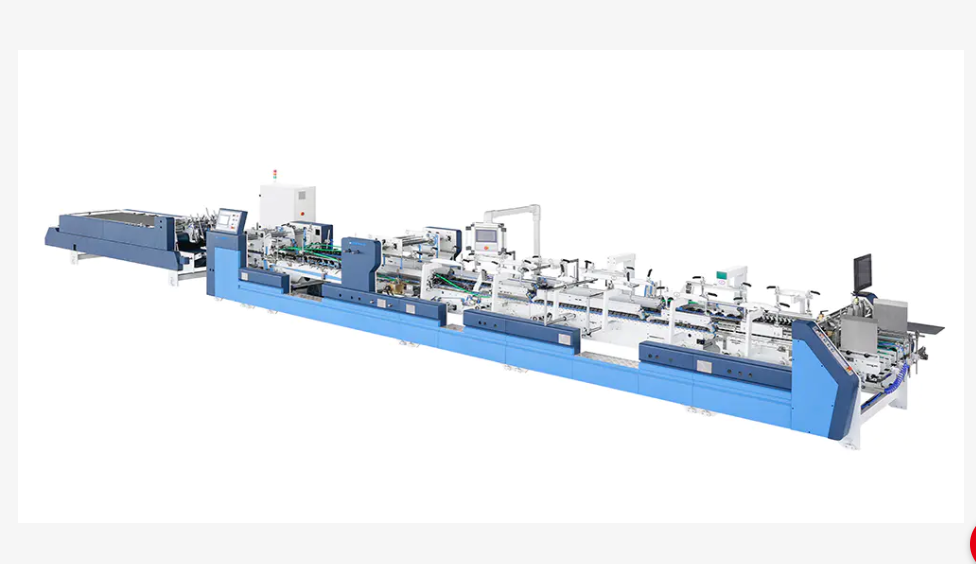

The European packaging scene is humming with two demands—speed and sustainability—and the straight-line carton folder gluer machine is built for both. Modern servo drives send belts racing at blistering pace while drawing noticeably less energy than the old clutch setups, letting e-commerce hubs keep same-day dispatch promises without adding staff.

PPWR-ready glue stations are just as vital. Italian-made electromagnetic valves lay down micro-dots of water-based adhesive, trimming glue use to a trickle and leaving recycled fibres unharmed so the board can head straight back to the mill. Tool-free doctor blades and RFID-coded cartridges shrink change-overs to a coffee-break length, a pace pharmaceutical printers rely on when antibiotic batches arrive with little notice.

Digital add-ons finish the job. An in-line camera cross-checks every glue line against the code on the blank; if a dot is absent, a waste gate flicks the carton aside in the blink of an eye, shielding the packer—and the brand—from recall risk. With labour scarce and energy costs still creeping up, buying a high-speed, low-waste folder gluer is no longer a capital luxury; it is the affordable policy for keeping shelf space tomorrow.

Today’s Carton Folder Gluer