The industrial hose market is poised for substantial growth in the coming years, driven by increasing demand across various industry verticals such as automotive, water and wastewater management, oil and gas, chemicals, infrastructure, food and beverages, agriculture, and mining. As per recent market analysis, the global industrial hose market size is projected to surge from US$ 14,659.29 million in 2024 to an impressive US$ 27,399.42 million by 2031, growing at a robust Compound Annual Growth Rate (CAGR) of 9.6% between 2025 and 2031. This blog post delves into the market dynamics, material types, industry applications, regional insights, and emerging trends that are shaping the future of the industrial hose market.

Understanding Industrial Hoses and Their Importance

Industrial hoses are flexible tubes designed to transport fluids, gases, or solids in various industrial applications. They are critical components in numerous sectors, enabling efficient fluid transfer while ensuring safety and operational reliability. Depending on the intended use, industrial hoses are manufactured from various materials like rubber, PVC, polyurethane, silicone, and others, each providing unique benefits such as chemical resistance, flexibility, durability, and temperature tolerance.

Market Size and Growth Outlook

The projected growth trajectory of the industrial hose market highlights the rising industrialization and infrastructure development worldwide. With a market valuation expected to reach nearly US$ 27.4 billion by 2031, the sector’s expansion is fueled by the increasing demand for efficient fluid handling systems in both established and emerging economies. The CAGR of 9.6% underscores strong investor confidence and the continual innovation in hose technology.

Key Material Types Driving Market Growth

The industrial hose market is segmented by material type, each offering distinct advantages tailored to specific industry needs:

-

Rubber Hoses: Dominating the market due to their excellent flexibility, abrasion resistance, and ability to withstand harsh environmental conditions. Rubber hoses are widely used in automotive, construction, and oil & gas sectors.

-

PVC Hoses: Known for their lightweight and cost-effectiveness, PVC hoses are popular in water management, agriculture, and chemical applications.

-

Polyurethane Hoses: These hoses provide superior abrasion resistance and elasticity, making them ideal for pneumatic tools, mining, and food & beverage industries.

-

Silicone Hoses: Valued for their high-temperature tolerance and chemical inertness, silicone hoses are increasingly utilized in food processing, pharmaceuticals, and automotive sectors.

-

Others: This category includes hoses made from specialty materials such as Teflon, nitrile, and composites, often used in niche applications requiring unique chemical or temperature resistance.

Industry Vertical Analysis

The industrial hose market spans a wide range of industries, each contributing to overall market growth:

-

Automotive: The automotive sector leverages industrial hoses extensively for fuel lines, brake systems, coolant transfer, and air conditioning. The rising demand for lightweight and durable hoses aligns with the industry’s focus on vehicle efficiency and emissions reduction.

-

Water and Wastewater: Industrial hoses play a crucial role in water treatment plants and wastewater management systems. The growth of urban infrastructure and strict environmental regulations are key factors driving the demand in this vertical.

-

Oil and Gas: One of the largest consumers of industrial hoses, the oil and gas sector requires hoses that can handle high pressures and harsh chemicals. With the ongoing global energy demand and offshore drilling activities, this segment presents significant growth opportunities.

-

Chemicals: Chemical processing industries demand hoses with high resistance to corrosive substances and extreme temperatures, fueling innovation in material technologies.

-

Infrastructure: Construction and infrastructure projects use industrial hoses for concrete pumping, dewatering, and pneumatic systems. The global surge in infrastructure investments is a major market driver.

-

Food and Beverages: Sanitary hoses with compliance to food safety standards are essential in beverage bottling, dairy processing, and other food-related applications.

-

Agriculture: Industrial hoses are used for irrigation, pesticide spraying, and water transfer in agriculture, where efficiency and durability are paramount.

-

Mining: The mining sector requires hoses that can withstand abrasive materials, high pressures, and extreme conditions, contributing to steady demand.

-

Others: This includes sectors such as pharmaceuticals, manufacturing, and energy, which also contribute to market expansion.

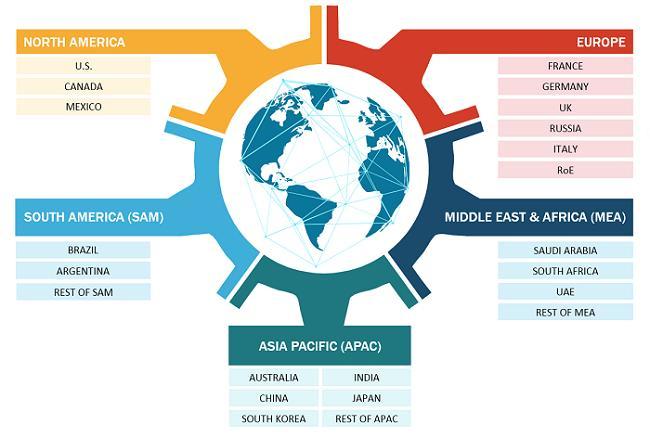

Regional Market Insights

The industrial hose market exhibits diverse regional dynamics driven by varying industrial activity, regulatory environments, and infrastructure investments:

-

North America: The region holds a significant market share due to advanced industrial infrastructure, high automotive production, and stringent environmental regulations that promote the use of advanced hose technologies.

-

Europe: Europe is characterized by high adoption of industrial hoses in chemicals, automotive, and food sectors, supported by a strong regulatory framework and focus on sustainability.

-

Asia-Pacific: The fastest-growing market region, Asia-Pacific benefits from rapid industrialization, urbanization, and infrastructure development, particularly in China, India, and Southeast Asia.

-

Middle East & Africa: Driven largely by the oil and gas industry, the Middle East remains a key market, while Africa is gradually expanding its industrial base.

-

Latin America: Growth is supported by agricultural activities and emerging industrial sectors, with Brazil and Mexico leading the market.

Trends Shaping the Industrial Hose Market

Several key trends are influencing the industrial hose market landscape:

-

Technological Innovation: Advancements in material science and manufacturing processes are leading to hoses with improved performance characteristics, such as enhanced flexibility, chemical resistance, and longer service life.

-

Sustainability Focus: There is a growing emphasis on eco-friendly materials and manufacturing practices. Biodegradable hoses and recyclable materials are gaining traction.

-

Customization and Automation: Increasing demand for tailor-made hoses that meet specific industrial requirements is pushing manufacturers to adopt automated production technologies.

-

Smart Hose Solutions : Integration of sensors and IoT technology into industrial hoses for real-time monitoring of pressure, temperature, and wear is emerging, enabling predictive maintenance and reducing downtime.

-

Regulatory Compliance : Compliance with stringent safety and environmental regulations continues to drive demand for high-quality hoses, especially in sensitive sectors like food and pharmaceuticals.

Growth Opportunities and Challenges

The industrial hose market presents lucrative opportunities for manufacturers and investors:

-

Emerging Markets : Rapid industrialization and infrastructure projects in emerging economies offer expansive growth potential.

-

Cross-Industry Applications : Expanding applications across diverse industries such as pharmaceuticals, electronics, and renewable energy open new avenues.

-

Aftermarket Services : Growing focus on maintenance, repair, and replacement services creates additional revenue streams.

However, challenges remain, including fluctuating raw material prices, the need for constant innovation, and competition from alternative fluid transfer technologies.

Conclusion

The industrial hose market is on a strong growth path, driven by expanding industrial activities, technological advancements, and evolving industry requirements. With a projected market size approaching US$ 27.4 billion by 2031 and a CAGR of 9.6%, the industry is set to witness dynamic growth across all major regions and sectors. Manufacturers who invest in innovation, sustainability, and customized solutions will be best positioned to capitalize on the expanding opportunities in this essential market segment.

Also Available in: