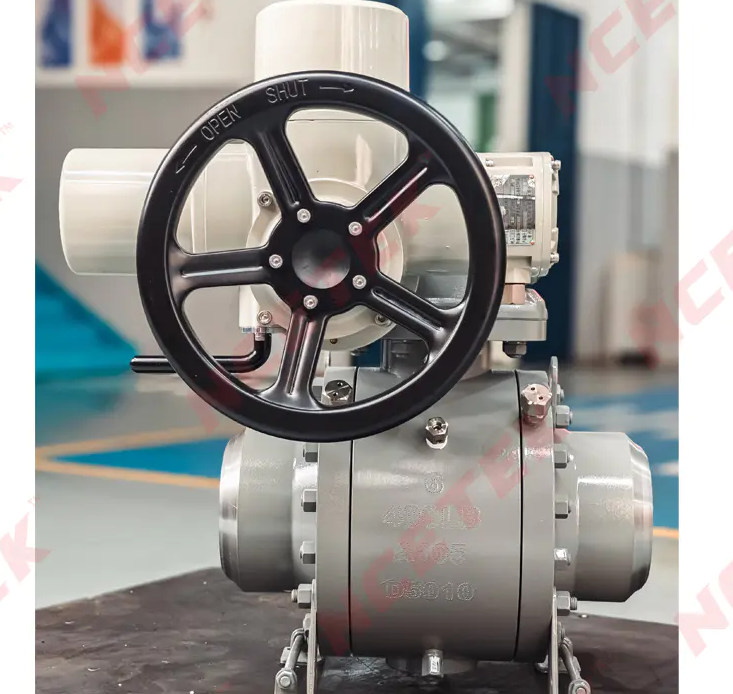

Slurries love to chew valves, yet the Metal Seat Ball Valve treats grit as a mere nuisance. Solid particles that would embed and shred soft seats meet a hardened metal surface that refuses to give way. Each stroke of the ball acts like a lathe tool, skimming built-up residue off the seat instead of letting it pack into a leakage path. The result is a valve that continues to rotate smoothly after months of ash, sand or catalyst fines have passed through. Maintenance teams report less frequent replacement of actuators and gearboxes because torque stays low; the ball does not wedge into a damaged seat. For tailings lines, frac-water manifolds or fly-ash handling, this durability means predictable shut-offs and fewer unplanned outages. The valve’s full-bore design also keeps velocity steady, discouraging the settling that turns pipelines into grinding rods. By surviving the abrasive onslaught, the metal-seated version turns the cost center of valve spares into a footnote, letting operators focus on throughput rather than parts lists.

Поиск

Категории

- Művészet

- Kézműves

- Tánc

- Italozás

- Film

- Fitness

- Étel

- Játékok

- Kertészet

- Egészség

- Otthon

- Irodalom

- Zene

- Hálózat

- Egyéb

- Party

- Vallás

- Vásárlás

- Sportok

- Színház

- Wellness

Больше

Lost Mary Flavors Guide – Discover the Best Tastes for Every Vaper

When it comes to rich taste profiles and smooth vaping satisfaction, Lost Mary flavors continue...

Potting Compound Market: Trends, Growth Drivers, and Future Outlook

Introduction

Potting compounds play a critical role in protecting electronic and electrical...

Cardiac Ablation Devices Market Overview, Outlook, CAGR, Growth, Share, Value

"Executive Summary Cardiac Ablation Devices Market :

CAGR Value

The global cardiac...

Craft Beer Market Dynamics: Key Drivers and Restraints 2025 –2032

Executive Summary Craft Beer Market: Growth Trends and Share Breakdown

CAGR Value

The...

Precast Concrete Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

Precast Concrete Market Segmentation, By Product Type (Columns and Beams, Walls and...