Pet Preform Mold serves as a critical component in bottle production, shaping plastic preforms that later become beverage containers, water bottles, and packaging for consumables. Mold design, material selection, and manufacturing precision all contribute to consistent preform quality, influencing final bottle performance.

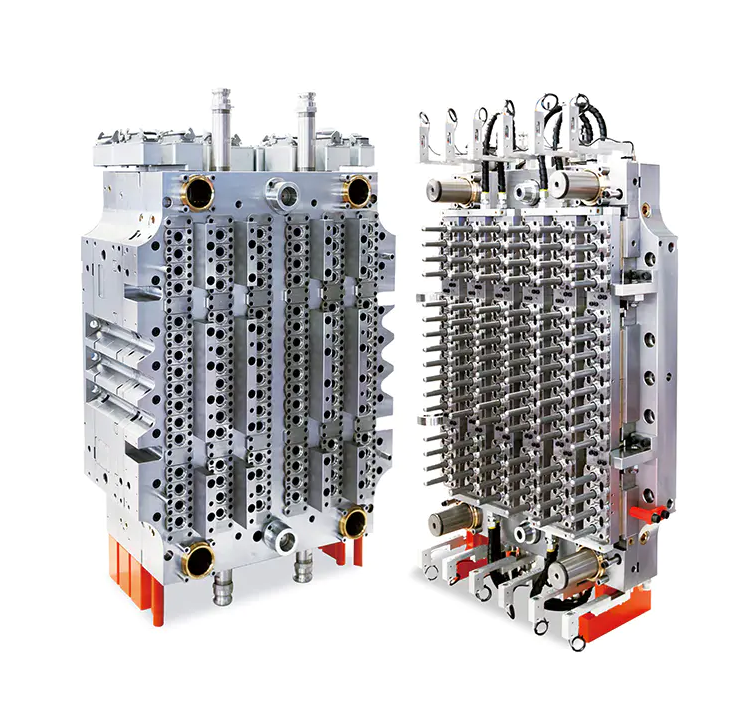

Precision in mold cavities determines uniformity. Each cavity must produce preforms with exact dimensions, wall thickness, and weight distribution. Pet Preform Mold requires tight tolerances to prevent defects, ensure reliable blow molding, and maintain consistent appearance and functionality across batches.

Thermal management affects cycle time and material performance. Heating and cooling systems integrated within Pet Preform Mold control plastic temperature, enabling uniform flow and reducing internal stress. Proper thermal balance prevents warping, incomplete fills, or deformation, supporting high-speed production without sacrificing quality.

Material selection impacts durability and wear resistance. Stainless steel and treated alloys provide strength to withstand repeated thermal cycles, pressure, and abrasion. Pet Preform Mold requires materials that resist corrosion and maintain dimensional stability over extended production periods.

Injection points, gates, and runners influence preform flow. Even distribution of molten PET prevents bubbles, streaks, and weak spots. Pet Preform Mold engineering ensures smooth material flow, reducing scrap and maintaining mechanical properties in finished preforms.

Maintenance and cleaning affect operational efficiency. Pet Preform Mold requires regular inspections, lubrication, and cleaning to prevent residue buildup and preserve cavity integrity. Proper care extends mold life and ensures continued production reliability.

Customization allows adaptation for different bottle sizes and shapes. Adjustable molds can produce preforms for small, medium, or large containers while maintaining consistency. Pet Preform Mold flexibility supports diverse product lines without requiring entirely new tooling.

Automation integration increases productivity. Pet Preform Mold can be paired with injection machines, robotic handlers, and monitoring systems to streamline production, reduce human error, and maintain consistent quality. Automated systems allow high-volume operations to run efficiently.

Testing and quality assurance verify dimensions, weight, and clarity. Sample preforms are measured for compliance with design specifications, ensuring each mold cavity functions properly. Pet Preform Mold performance directly influences downstream processes, including blow molding, labeling, and filling.

Overall, Pet Preform Mold combines precision, durability, and efficiency. Careful design, material selection, and thermal management enable manufacturers to produce consistent preforms, supporting reliable beverage packaging and reducing waste. Well-maintained molds allow smooth production and contribute to cost-effective operations.