Introduction to Response Speed

In industrial and commercial applications, the responsiveness of a weighing system is critical for efficiency and accuracy. An Electronic Weighing Indicator serves as the central component that displays weight readings from connected load cells. The speed at which it updates measurements and reacts to changes in weight directly impacts workflow, decision-making, and operational efficiency. Fast response times are particularly crucial in high-throughput environments, such as warehouses, production lines, or retail settings, where delayed readings can lead to errors, slow processing, and reduced productivity.

Factors Affecting Response Time

The response speed of an electronic weighing indicator depends on the performance of its internal processor, the quality of the connected load cells, and the efficiency of its software algorithms. High-quality indicators feature fast analog-to-digital converters that translate sensor signals into accurate digital weight readings almost instantly. Advanced signal filtering and processing ensure stability without sacrificing speed, providing real-time data even when handling fluctuating or rapidly changing loads. Indicators with slower processing may require additional stabilization time, which can be detrimental in fast-paced operational environments.

Real-Time Data Accuracy

Beyond speed, real-time performance also encompasses the ability to deliver accurate readings consistently. A responsive Electronic Weighing Indicator can immediately detect weight changes and display the correct value without noticeable lag. This is essential for applications that require dynamic weighing, such as filling lines, checkweighing stations, or batching processes. Indicators that combine rapid response with precise measurement allow operators to make quick decisions based on reliable data, ensuring both efficiency and quality control.

Industrial and Commercial Applications

In high-demand environments, such as logistics centers or retail stores, a fast and reliable weighing indicator improves workflow efficiency. Products can be weighed continuously without interrupting operations, reducing bottlenecks at stations where multiple transactions or measurements occur. For industries where time-sensitive measurements are critical, real-time responsiveness helps maintain accuracy and prevents operational delays. This makes electronic weighing indicators an essential tool for businesses aiming to improve productivity and minimize errors in fast-paced settings.

Design Features Enhancing Performance

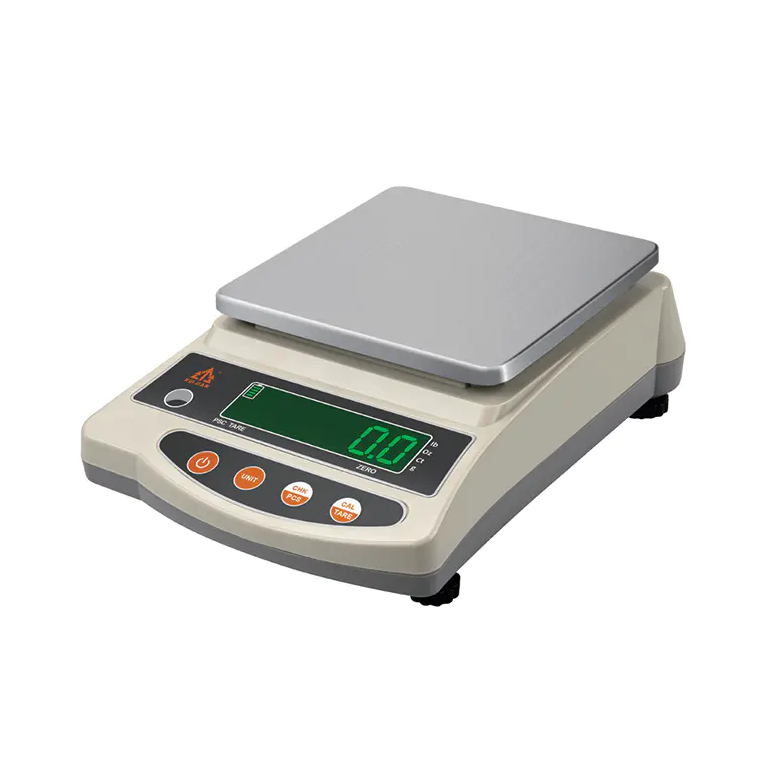

Modern electronic weighing indicators often include features designed to improve speed and real-time performance. Large, high-resolution displays update readings instantly, allowing operators to view results clearly. Connectivity options, such as USB, Ethernet, or wireless interfaces, enable rapid data transfer to external systems or databases. Some indicators also feature programmable functions for filtering or averaging weight signals, allowing for stable readings without compromising real-time responsiveness. These design elements ensure that the indicator performs reliably under continuous, high-volume use.

Maintenance and Reliability Considerations

Maintaining the optimal response speed of an electronic weighing indicator requires routine care. Regular calibration, inspection of load cells, and software updates ensure consistent performance. Durable construction and quality components reduce the risk of performance degradation over time, allowing the indicator to maintain fast, accurate readings even in demanding environments. By following manufacturer guidelines, businesses can preserve both the responsiveness and longevity of the equipment.

The responsiveness and real-time performance of an Electronic Weighing Indicator are critical for accuracy, efficiency, and operational reliability. High-quality indicators combine fast processing, precise sensor integration, and intelligent software to deliver immediate, stable weight readings. This makes them indispensable in commercial, retail, and industrial applications where speed and accuracy are essential. Investing in a responsive electronic weighing indicator ensures consistent performance, enhanced productivity, and reliable results under demanding operational conditions.