In an era defined by climate action and technological leaps, Special Shaped Sintered NdFeB Magnets are emerging as unsung heroes in the global push toward sustainability. As industries pivot to meet carbon neutrality goals and embrace smart manufacturing, these high-performance magnets—crafted into bespoke geometries—are enabling breakthroughs across electric vehicles, renewable energy systems, and advanced robotics. Unlike conventional designs, Special Shaped Sintered NdFeB Magnets combine unparalleled magnetic strength with adaptability, making them indispensable for applications demanding precision, efficiency, and environmental responsibility.

The urgency to decarbonize industries has thrust these magnets into the spotlight. Electric vehicle manufacturers, for instance, rely on custom-shaped magnets to optimize motor efficiency, extending battery life and reducing energy waste. Similarly, wind turbine generators leverage their unique configurations to enhance power output, aligning with global renewable energy targets. The rise of automation and AI-driven robotics further amplifies demand, as irregularly shaped magnets enable compact, high-torque actuators essential for delicate surgical robots or agile industrial arms.

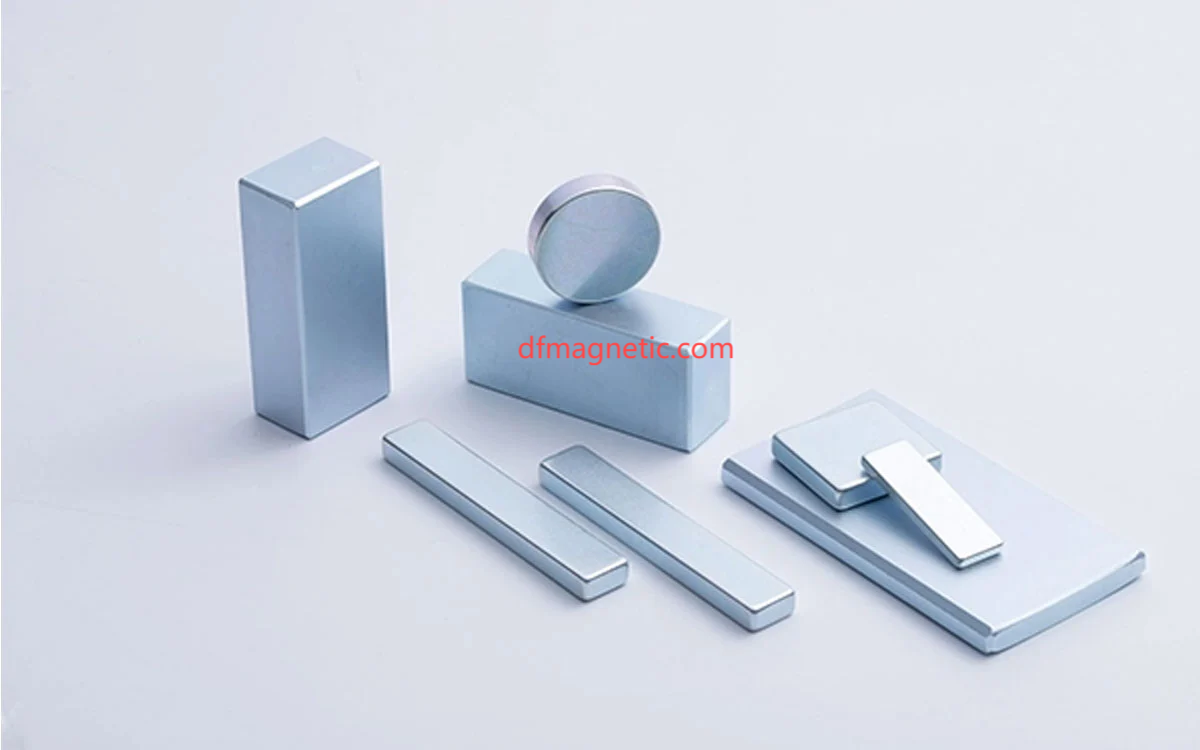

Innovation in material science plays a pivotal role. Advanced sintering techniques now allow manufacturers to produce magnets in intricate forms—from curved segments for aerospace sensors to micro-components for consumer electronics—without compromising magnetic stability. These advancements not only meet stringent performance criteria but also align with circular economy principles. By minimizing material waste during production and enabling end-of-life recyclability, Special Shaped Sintered NdFeB Magnets address both industrial and ecological priorities.

Regulatory landscapes are also shaping adoption. Regions like the EU and North America increasingly mandate eco-friendly certifications for imported components, pushing manufacturers to adopt greener processes. Magnets crafted with responsibly sourced rare-earth elements and low-carbon production methods are gaining traction, particularly in sectors like automotive and renewable energy, where sustainability credentials directly influence market access.

The fusion of customization and sustainability opens doors to untapped markets. In the biomedical field, magnets tailored for MRI machines or wearable health monitors demonstrate how precision engineering enhances patient care. Meanwhile, the consumer electronics sector benefits from ultra-thin, lightweight designs that power next-gen devices without sacrificing performance.

As global industries accelerate their green transitions, Special Shaped Sintered NdFeB Magnets stand at the intersection of innovation and necessity. Their ability to merge form, function, and environmental stewardship positions them not just as components, but as catalysts for a cleaner, smarter future. In this transformative age, these magnets are more than tools—they are the building blocks of progress.

dfmagnetic.com