When selecting a material for watercraft, especially inflatables, the choice of fabric is more than aesthetic—it determines the boat’s lifespan, safety, and usability. Among the various materials available, PVC Inflatable Boat Fabric has emerged as a reliable and popular choice in both commercial and recreational sectors. Its blend of physical toughness and functional adaptability makes it a top-tier solution for crafting long-lasting inflatable boats.

Why PVC is Trusted for Inflatable Boat Applications

PVC (Polyvinyl Chloride) stands out in the marine fabric world due to its robust set of properties. As a durable inflatable boat material, PVC offers excellent resistance to abrasion, punctures, and weathering—factors that frequently compromise boat longevity.

In terms of outdoor performance, PVC-coated fabrics are engineered to handle UV radiation, saltwater exposure, and chemical contact. Unlike natural fabrics or cheaper synthetic alternatives, PVC does not degrade easily in sunlight or harsh marine environments, preserving both the strength and flexibility of the boat over extended use.

Exceptional Resistance for Long-Term Use

One of the core benefits of PVC fabrics is their remarkable resistance to elements:

UV Resistance: Prevents degradation and color fading caused by sun exposure.

Salt and Chemical Resistance: Maintains structural integrity in seawater or chemically-treated freshwater.

Abrasion Resistance: Protects against rocks, docks, and equipment contact, extending service life.

Air-Tight Welds: PVC supports thermal bonding, ensuring airtight seams essential for inflatable structures.

These characteristics make it especially suitable for heavy-duty inflatables, such as rescue rafts, professional-grade dinghies, and high-pressure flooring components.

Practical Use Cases in the Real World

PVC Inflatable Boat Fabric is used across a wide range of scenarios:

Recreational Boats: Lightweight and easy to fold, PVC boats are ideal for casual boating and travel.

Fishing Kayaks: With excellent puncture resistance, PVC makes a safe option for shallow waters or rocky conditions.

Rescue & Military Boats: Trusted for quick deployment and durability in emergency or tactical settings.

Floating Platforms: Used in inflatable docks and pontoons where weather-resistance is critical.

In all these cases, the material’s durability means fewer repairs, longer service intervals, and lower long-term costs.

Balancing Cost, Performance, and Customization

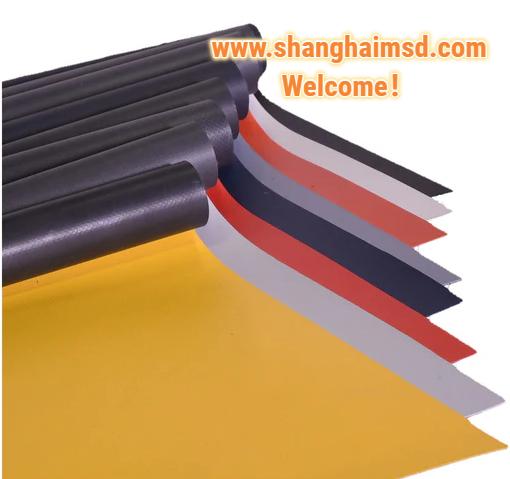

PVC also offers significant manufacturing and operational advantages. Compared to Hypalon or TPU, PVC is more cost-effective, making it accessible for large-scale production without sacrificing performance. Additionally, the fabric allows for color customization, anti-slip surface coatings, and different thicknesses to meet varied market needs. These customization options ensure both brand identity and functional precision.

For buyers and builders looking to source high-quality, proven PVC Inflatable Boat Fabric, it's not just about cost—it's about consistent performance in demanding environments. To explore material solutions that balance strength, flexibility, and affordability, visit shanghaimsd.com .